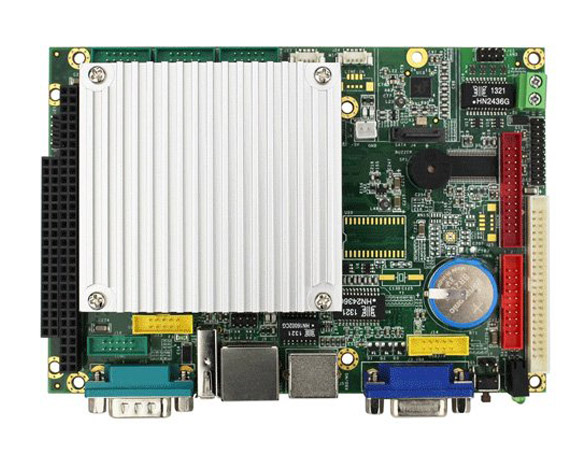

Single board computers, often called SBCs, are compact computers built onto a single circuit board. Unlike a traditional desktop PC, all the key components are placed together. This includes the processor, memory, storage options, and input and output connections.

Because everything is on one board, SBCs are small, efficient, and reliable.

In recent years, single board computers have become more important across many industries. Businesses now need systems that are powerful, flexible, and easy to deploy. SBCs meet these needs well.

They can be used in factory automation, data collection, transport systems, and remote monitoring. Their small size makes them ideal for installations where space is limited.

Technology trends are also driving the growth of SBCs. Edge computing, the Internet of Things (IoT), and smart manufacturing all rely on compact computing devices. Instead of sending data to the cloud, SBCs allow processing to happen close to the source. This improves speed, reliability, and security.

Modern single board computers are far more capable than earlier models. They support advanced operating systems, fast networking, and a wide range of industrial interfaces. Many are designed to operate in harsh environments, including high temperatures and dusty conditions.

This makes them a practical choice for industrial and commercial use.

In this guide, we will explain how single board computers work, where they are used, and how to choose the right one for your project. Whether you are planning a new system or upgrading an existing one, understanding SBCs can help you make better technical decisions.

How Single Board Computers Work

A single board computer contains all the main parts of a computer on one circuit board. This makes it different from a traditional PC, where components are spread across several boards and cables. The compact design helps reduce power use, cost, and points of failure.

At the centre of an SBC is the processor, also known as the CPU. This is the part that runs software and handles instructions. SBC processors can be based on ARM or x86 architecture.

ARM processors are common in low-power systems, while x86 processors are often used when higher performance or compatibility with PC software is needed.

Memory is another key part of a single board computer. This includes RAM, which is used while the system is running, and storage, which holds the operating system and applications. Storage may be built in or added using SD cards, eMMC, or solid-state drives. This flexibility allows SBCs to be adapted to different tasks.

Input and output connections, often called I/O, are built directly onto the board. These may include USB ports, Ethernet, serial ports, digital inputs, and display outputs. Many SBCs also support industrial interfaces such as GPIO, CAN bus, or Modbus.

This allows them to connect easily to sensors, machines, and control systems.

Most single board computers run a full operating system. Common choices include Linux distributions, Windows IoT, or real-time operating systems. The operating system controls the hardware and allows applications to run reliably. This makes SBCs suitable for both simple control tasks and more complex computing workloads.

Because everything is integrated onto one board, single board computers are reliable and easy to install. They can be mounted inside enclosures, panels, or machines with minimal wiring. This makes them well suited to industrial environments where long-term stability is important.

Industrial Applications of Single Board Computers

Single board computers are widely used in industrial environments. Their small size, low power use, and flexible design make them suitable for many different applications. As industries move towards automation and digital systems, SBCs play an important role.

One common use is in factory automation. SBCs can control machines, monitor production lines, and collect data from sensors. They are often used in human–machine interfaces, where operators need clear and reliable system control. Because SBCs support modern operating systems, they can run visual dashboards and control software with ease.

SBCs are also used for industrial data logging and monitoring. They collect information such as temperature, pressure, vibration, or energy use. This data can be stored locally or sent to a central system for analysis.

By processing data at the edge, SBCs reduce network traffic and improve response times.

In transport and infrastructure, single board computers support systems such as ticketing, signalling, and vehicle monitoring. Their compact design allows them to be installed in tight spaces. Many industrial SBCs are built to withstand shock, vibration, and wide temperature ranges, which is essential for mobile and outdoor environments.

Another growing area is industrial IoT and edge computing. SBCs act as gateways between machines and cloud platforms. They filter, process, and secure data before it is transmitted. This improves system reliability and reduces delays. It also helps organisations meet security and compliance requirements.

Single board computers are also used in robotics and machine vision. They can control motors, process camera data, and run AI-based inspection tools. This supports tasks such as quality control and predictive maintenance.

As processing power increases, SBCs continue to replace larger and more expensive systems.

Overall, single board computers provide a reliable and cost-effective solution for modern industrial systems. Their ability to adapt to different tasks makes them a strong choice for both new installations and system upgrades.

Single Board Computers Compared to Traditional Alternatives

When planning an industrial system, it is important to choose the right type of hardware. Single board computers are often compared with PLCs, microcontrollers, and embedded PCs. Each option has its strengths, but they are designed for different tasks.

PLCs are commonly used in industrial control. They are very reliable and work well for simple, repeatable processes. However, they can be expensive and limited in flexibility. PLCs are not ideal for tasks that need advanced graphics, data processing, or modern networking.

In these cases, an SBC can offer more power and greater software choice.

Microcontrollers are another alternative. They are low cost and use very little power. This makes them suitable for simple control tasks, such as switching or basic sensing. However, microcontrollers do not run full operating systems.

They also have limited memory and processing power. SBCs are a better choice when an application needs complex logic, connectivity, or user interfaces.

Embedded PCs provide high performance and good compatibility with desktop software. They are often used in demanding industrial applications. However, they are usually larger, more expensive, and use more power.

Single board computers can deliver similar performance in a smaller and more efficient form factor.

Single board computers sit between these options. They offer more power than microcontrollers and more flexibility than PLCs. At the same time, they are smaller and more cost-effective than embedded PCs. This balance makes SBCs suitable for a wide range of industrial and commercial uses.

Choosing between these technologies depends on the application. Factors such as performance, environment, cost, and long-term support all play a role. In many modern systems, SBCs provide the best overall solution.

Choosing the Right Single Board Computer for Your Project

Choosing the correct single board computer is an important step in any project. The right choice can improve performance, reliability, and long-term value. The wrong choice can lead to higher costs and future problems. It is important to consider the full system, not just the board itself.

The first factor to look at is processing power. Different applications require different levels of performance. Simple monitoring tasks may only need a low-power processor. More demanding applications, such as image processing or data analysis, need faster CPUs and more memory.

It is also important to consider whether an ARM or x86 processor is more suitable for your software.

Connectivity and input and output options are also critical. Check that the SBC supports the interfaces you need. This may include Ethernet, USB, serial ports, or digital I/O. Industrial applications often require specific interfaces such as CAN bus or GPIO.

Choosing a board with the right connections reduces the need for extra hardware.

Environmental conditions should never be overlooked. Industrial SBCs are often installed in harsh locations. Temperature range, vibration resistance, and protection against dust or moisture are important.

Not all single board computers are designed for these conditions, so it is important to choose a model built for industrial use.

Long-term availability and support are also key considerations. Many industrial systems are expected to run for years. Choosing an SBC with long product life cycles and stable software support helps reduce risk. This is especially important for maintenance, updates, and future system expansion.

Finally, consider power consumption and mounting options. Low-power SBCs are ideal for remote or energy-sensitive systems. Flexible mounting makes installation easier and helps with system design.

By carefully reviewing these factors, businesses can select a single board computer that meets both current and future needs.

Software Platforms and Operating System Options

The operating system plays a key role in how a single board computer performs. It controls the hardware and allows applications to run reliably. Choosing the right software helps improve stability and security.

Linux is the most common choice for SBCs. It is flexible, well supported, and widely used in industrial systems. Custom versions can be built to suit specific applications, making Linux suitable for automation, monitoring, and edge computing.

Windows IoT is used on some x86-based SBCs. It is helpful when systems rely on Windows software or tools. However, it usually needs more system resources than Linux.

Some applications need fast and predictable responses. In these cases, a real-time operating system may be required. RTOS platforms are designed for control and time-critical tasks.

Remote updates, security patches, and long-term support should also be considered. Good software management reduces downtime and helps systems run reliably over many years.

Future Trends in Single Board Computing

Single board computers continue to evolve as technology and industry needs change. One major trend is the growth of edge computing. More data is now processed close to where it is created. SBCs make this possible by offering strong performance in a compact form. This reduces delays and improves system reliability.

Artificial intelligence is also becoming more common at the edge. Modern SBCs can now support AI workloads such as image recognition and predictive maintenance. This allows faster decision-making without relying on cloud services.

As processors become more powerful, this trend will continue to grow.

Connectivity is another key area of development. Faster Ethernet, 5G support, and improved wireless options are becoming standard. This helps SBCs integrate more easily into industrial networks and remote systems.

Long-term availability and sustainability are also gaining importance. Manufacturers are focusing on energy-efficient designs and extended product lifecycles. This supports stable systems and reduces waste.

As these trends continue, single board computers will remain a key part of modern industrial and embedded systems.

Supporting Reliable Industrial Systems with Single Board Computers

Single board computers have become a trusted solution for many industrial and commercial applications. They offer a balance of performance, flexibility, and efficiency that suits modern system design. From automation and monitoring to edge computing and AI, SBCs support a wide range of uses.

Choosing the right single board computer requires careful consideration. Hardware performance, connectivity, environmental resistance, and long-term availability all play an important role. Software support and operating system choice are equally important for system stability and security.

Working with an experienced supplier can make this process easier. DSL Industrial Computing supports businesses with industrial-grade computing solutions designed for long-term use. With a wide range of single board computers and related expertise, DSL can help match the right technology to each application.

As industrial systems continue to evolve, single board computers will remain a key building block. With the right approach and the right hardware partner, businesses can deploy reliable systems that meet both current and future requirements.

DSL Industrial Computing supplies reliable industrial computers and single board computers for demanding environments. Our team can help you select the right solution for your application.

Contact us today to discuss your requirements and get expert advice.